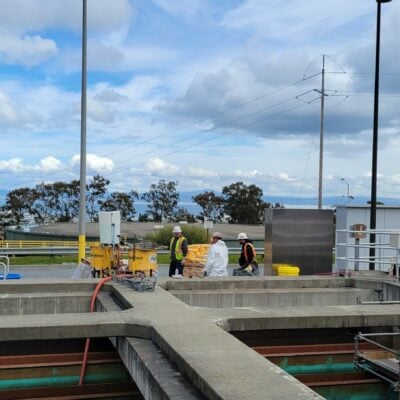

The scope of this project entails an operational upgrade to the existing backwash underdrain system that had failed on 6 filter locations. The project is broken down into 2 phases so that only 3 of the filters were offline for construction at a time. The project involves removal of the existing filter media and demo of the failed plastic block underdrains. Then a grout leveling course is installed to bring both sides of a filter to the same elevation. A complete new stainless steel underdrain system was then installed and anchored to the filter floor. Once installed the new filter media was placed inside the drains, and then brought back online to observe the testing and commissioning of the new underdrain system. The steel main air header pipe also needed to be recoated as well as some concrete repair work on the filters themselves.